Crucible Furnaces & Ovens

Questions? Contact Us!

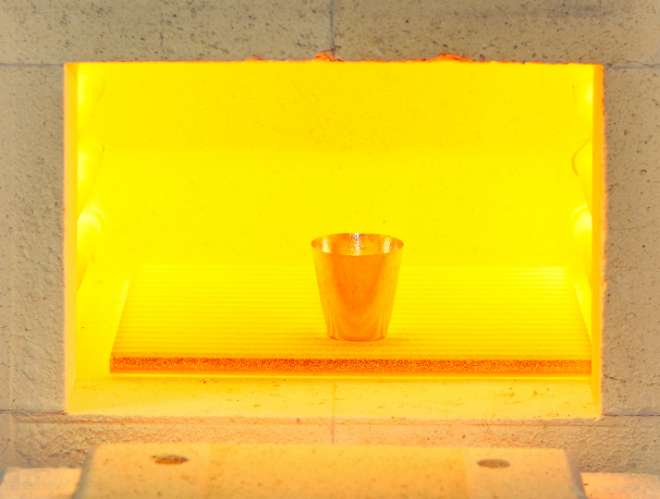

What is a Crucible Furnace?

A crucible furnace is a type of foundry furnace used for melting and casting metals that have a low melting point such as brass, bronze, and aluminum. They are one of the oldest types of melting ovens and among the most commonly used furnaces in the industry. The container that the metals and additives are placed in is referred to as the “crucible”, and is made of a heat-resistant material such as graphite, clay, or ceramic.

Crucible furnaces typically consist of a furnace chamber made of refractory material, which is heated by a fuel source such as natural gas, propane, or electricity. The crucible is placed inside the furnace chamber and heated until the metal inside it melts. Once the metal has melted, it can be poured into molds to create various shapes and forms. The crucible can be removed from the furnace chamber using tongs or other tools, and the molten metal can be poured into the molds.

Crucible ovens are categorized by how the molten metal is removed from the crucible:

- Tilting furnace: tilting the crucible to pour the metal into the mold.

- Bale-out furnace: metal is ladled out of the crucible.

- Lift-out furnace: both crucible and metal are removed from the furnace for direct pouring.

Applications of Crucible Furnaces

Crucible furnaces range in size from small, tabletop units used in jewelry making and small-scale metalworking to larger, industrial-scale furnaces used in larger foundries and manufacturing facilities. They are typically the go-to when small doses of low melting point alloy are required. The crucible furnace is ideal for laboratories where metal, glass, and pigment production take place, but can also be found in small businesses and vocational schools.

Learn More About Crucible Furnaces

Crucible furnaces are a critical part of any bronze or aluminum foundry and can provide value in other industrial applications. They are relatively easy to use and maintain, and are a cost-effective way to melt and cast small to medium-sized quantities of metal.

Contact our team today if you have any questions about the crucible oven and browse our full selection of products to find the perfect industrial furnace for your operation.

Address: 21294 Drake Rd., Strongsville, OH 44149 Phone: (440) 260-0364

Copyright Sentro Tech