What Is Ceramic Tubing? A Guide to Its Industrial Benefits and Applications

Learn all about ceramic tubing, a high-temperature solution for industrial furnaces, laboratories, and manufacturing. Discover its benefits, types, and applications.

Learn all about ceramic tubing, a high-temperature solution for industrial furnaces, laboratories, and manufacturing. Discover its benefits, types, and applications.

Discover the differences between fiberglass and ceramic fiber insulation in this comparative analysis. Learn why ceramic fiber insulation is the top choice for high-temperature industrial applications.

Molybdenum disilicide heating elements are revolutionizing industrial furnaces with their exceptional performance. Due to their stability, oxidation resistance, and durability, these elements are increasingly used in high-temperature applications.

Basic Oxygen Furnaces (BOFs) are prime players in contemporary steel manufacturing. They use high-purity oxygen to convert raw iron into high-quality steel, significantly enhancing steelmaking production efficiency and quality for industries of all types.

Learn about the tempering process in this comprehensive guide. Discover how tempering ovens enhance the toughness of metals, the types of metals suitable for tempering and a step-by-step guide to tempering metal.

Explore the vacuum furnace brazing process, get answers to questions like, “What is furnace brazing?” and learn the advantages of furnace brazing over traditional brazing methods.

In an era where precision, efficiency and environmental responsibility converge, heat treatment methodologies are undergoing transformative shifts. Vacuum furnaces, with their array of compelling advantages, are at the forefront of the heat treatment revolution.

When choosing the ideal furnace for your heat treatment needs, the decision often narrows down to two prominent contenders: tube furnaces and muffle furnaces.

When it comes to the world of dentistry, dental furnaces play a critical role in the production and maintenance of dental appliances, crowns, and other important structures.

In scientific research, experimentation, and industrial processes, the need for controlled heating and moisture removal is paramount. This is where laboratory furnaces and drying ovens come into play. As essential tools for various applications, lab furnaces and industrial drying ovens aim to alter material properties or prepare samples.

Few heat-treating furnaces offer the range of benefits and advantages of retort ovens. Their versatility, precision, containment, and durability make them ideal for everything from retort laboratories to heavy industrial applications.

One of the key components of any foundry operation is the foundry furnace, which is used to melt and shape metal materials into the desired form. There are five main types of foundry furnaces, each with its own unique characteristics and advantages.

Vacuum tube furnaces are essential tools in industries that utilize high-temperature processes. These furnaces operate in a vacuum or controlled atmosphere, making them ideal for various applications such as crystal growth, heat treatment and thin film deposition.

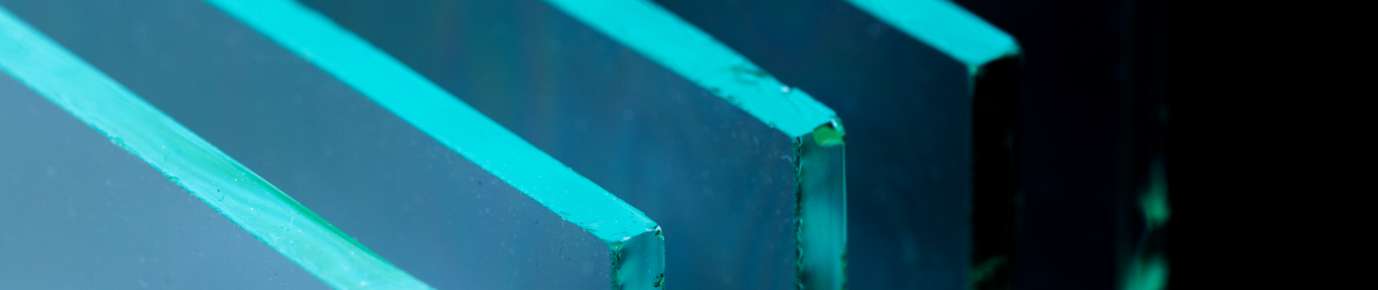

Fritted glass has become a trendy option in modern architecture. It is also widely used in laboratories and industrial applications as a filter or scrubber. But what is fritted glass? How is it made? In our article, we’ll discuss how glass fritting is used today. Learn how to manufacture fritted glass and how its versatility has made it a favorite in modern building designs.

Glass-melting furnaces are an integral part of the manufacturing process for a variety of industries and manufacturers. Most glass products today — from windows to bottles — make use of a glass-melting furnace at some point during the production process.

Industrial heating elements are essential components in industrial furnaces. Capable of generating heat for high-temperature applications, furnace heating elements are vital components in a number of manufacturing processes. The choice of heating element material is crucial, as it must be able to withstand the required operating temperatures of your application along with the necessary electrical resistance properties.

Silicon carbide has been used in manufacturing for over a century. Unique chemical properties make silicon carbide ideal for certain industrial applications. Since it is synthetically produced as silicon carbide powder, it brings up a very good question: Is silicon carbide a ceramic? And what is silicon carbide used for anyway?

Dozens of industries, laboratories and manufacturers rely on high-powered vacuum furnace systems to perform daily functions. From heat treatment to brazing and sanitation, vacuum furnaces perform a variety of duties that are crucial for a company to operate efficiently.

Inert gas technology is essential to operating high-temperature atmosphere vacuum furnaces, which manufacture critical components for a wide range of industries. Because of the crucial nature of these parts, it’s necessary to carefully control the furnace temperature. This article will answer the question, “What is inert gas technology?” and review the roles that airflow and air pressure play in the process.

The foundry process creates numerous products used in nearly every industry worldwide. But what is a foundry? Find out about industrial foundry work to understand this essential manufacturing process at Sentro Tech.

When working with glass, it’s essential to understand the relationship glass viscosity and temperature have with its final cooled form. Manufacturers use high-temperature glass furnaces and annealing ovens for various purposes, but without a proper understanding of how to measure viscosity during processes, glass workers will quickly find their finished products can become highly strained and often unusable.

What are the different types of ceramic materials? Learn more about the industrial ceramics process and how ceramic materials are used in modern manufacturing. Discover how ceramic raw materials are turned into finished products through sintering and heat treatment.

Untreated glass is brittle and can break easily and sometimes spontaneously. The process of annealing glass strengthens it, making the glass less likely to break. This article will answer the question, “What is annealed glass?” We’ll also look at the process of glass annealing and its benefits.

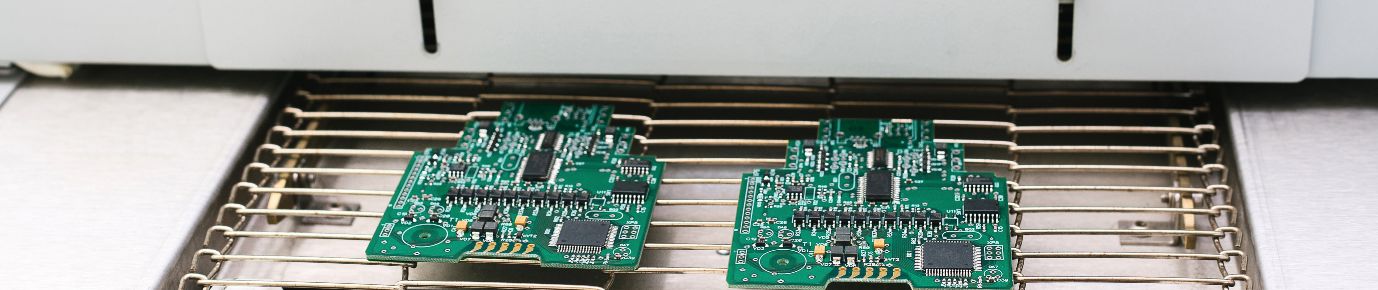

Ceramic manufacturing has come a long way since humanity made pottery using clay and other materials. While the technology has advanced, the ceramics manufacturing process has evolved with it to create modern materials used in everything from pottery, wall tiles and building materials to circuit boards and industrial ceramics products. In this article, we discuss the standard process of making ceramics using a number of different production techniques and equipment. From sintering at high temperatures to slip casting, let’s talk about the modern manufacturing process of ceramics.

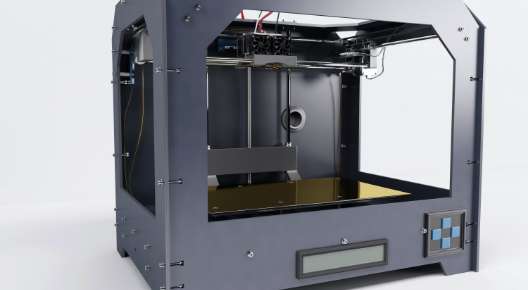

The 3D metal printing process can open doors to a new world of manufacturing capabilities for both technology and business. Sintered 3D printing minimizes tooling costs, dramatically reduces the cost per part and provides geometric freedom only possible with additive manufacturing processes. Additionally, 3D metal printing has improved automation, as printers can produce parts automatically from CAD design files. As one of the most heavily invested and fastest-growing technologies in the manufacturing industry, leading manufacturers are already using the 3D metal printing process to rapidly prototype and print parts on-demand to great success.

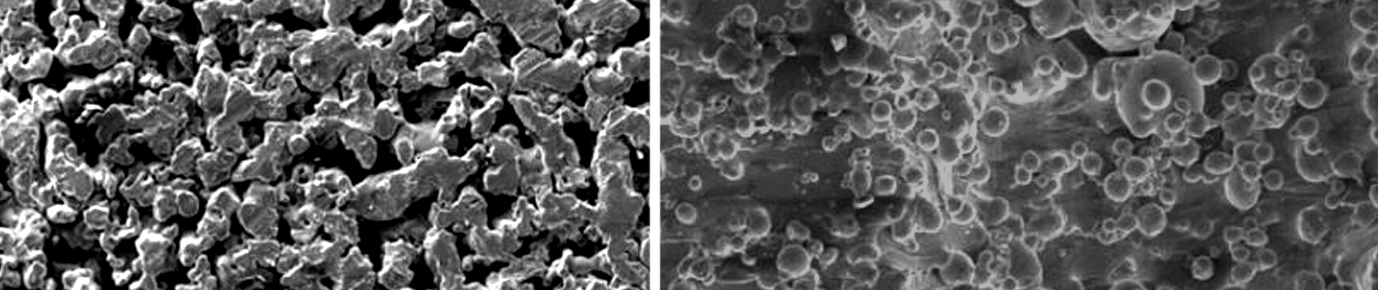

What Is The Sintering Process? Powder sintering is a manufacturing process that has been in use since the Industrial Revolution. Powder metallurgy is closely related to the ceramic sintering process, as both utilize a base powder component and apply heat to produce a hard, solid part. In this article we discuss the sintering process as […]

Pictures at the Sentro Tech Facility Here are a few recent photos that were taken of Sentro Tech employees at our Ohio manufacturing facility. We are proud to provide the best service and products in the high-temperature processing industry! Are you looking for a specific type of industrial furnace? SentroTech offers sintering furnaces, […]

Rapid Heating Furnace by SentroTech SentroTech Corp. has developed the STR- 1600C, a new rapid heating furnace that heats to 1500 degrees Celsius in just 15 minutes. With a max ramping rate of 100 degrees Celsius per minute, the STR- 1600C laboratory furnace allows for rapid heating under vacuum and controlled atmosphere. All of SentroTech’s […]

Sentro Tech Expansion to a New Premise May 14, 2012 — Every media outlet is crammed full with stories on how the recession continues to hit businesses. Countless companies are going out of businesses everyday and even major corporations are downsizing. It seems good economic news is hard to find. One bright light on the […]

Contact a Sentro Tech representative today to learn more about our high-temperature furnaces.

Contact UsAddress: 21294 Drake Rd., Strongsville, OH 44149 Phone: (440) 260-0364

Copyright Sentro Tech