Industrial 3D Printing Technology

Questions? Contact Us!

What is 3D printing?

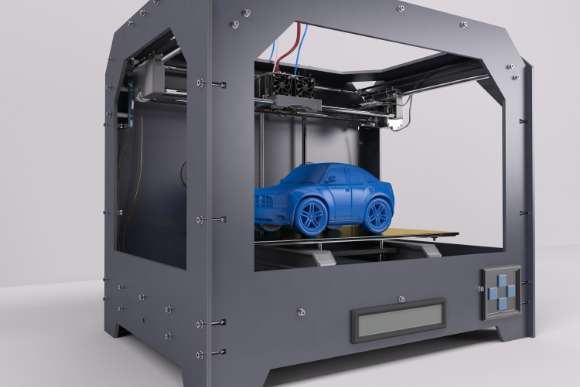

Originally introduced in 1980, additive manufacturing, more commonly known today as 3D printing, is a cost-effective method for creating plastic parts and prototypes. Advances in technology now allow for more sophisticated printers, making it easy for manufacturers to print three-dimensional parts using metal materials. Additionally, additive manufacturing also includes ceramics and gives injection molders an alternative process for building parts.

The ability to print a variety of materials with a computer-aided design (CAD) file makes 3D printing increasingly effective for both prototypes and certain production environments. Although start-up costs remain high, additive manufacturing’s convenience and volume production potential continue to make the 3D printing industry appealing to manufacturers. Notable major manufacturers like GE, Honeywell, and IBM, amongst others, already embrace 3D printing technology for parts production and prototype applications.

Industries We Serve

A variety of industries use 3D printing technology to create commercial metal parts. Manufacturers print these parts using:

- Aluminum

- Stainless steel

- Brass

- Copper

- Bronze

- Sterling silver

- Gold

- Platinum

- Titanium

- Hybrid ceramic compounds

Depending on the environment or application, manufacturers use common processes, like sintering, debinding, fusing, curing, heat treatment and more, to achieve results for finished parts. A high-temperature industrial furnace is then used to apply these treatments to 3D-printed parts or prototypes. In addition to a controlled heat environment, a versatile vacuum furnace supports a variety of atmospheres, including hydrogen, argon, or other inert gasses, to facilitate metal processing.

Vacuum Furnaces for 3D Printing

Integral for additive manufacturing, sintering furnaces, and dry ovens make 3D metal printing parts and prototypes accessible and cost-effective. Industrial vacuum furnaces deliver precise temperature control and uniform heating consistency. Additionally, depending on the materials used, a high-temperature sintering furnace makes it easy to control environments and atmospheres. Consider a Sentro Tech sintering furnace for your 3D metal printing needs.

Use Sentro Tech high-temperature furnaces for de-binding and sintering under a controlled atmosphere. The de-binding process applies heat to parts under a controlled partial vacuum argon atmosphere to remove the binder. De-binding partial pressure is typically between 3-30 Torr. After the de-binding process, increase the furnace temperature to metal sintering temperature. This forms dense metal parts either under vacuum, partial vacuum, or controlled positive atmosphere. Our high-temperature vacuum sintering furnace features a typical vacuum of 10-4 to 10-5 torr. And the partial vacuum argon atmosphere offers a typical vacuum from 3-300 torr. Positive atmosphere sintering features typical pressure from 760 to 1100 torr.

Sentro Tech offers a wide range of high-temperature furnaces, dry ovens, and heating equipment. Choose from standard models or custom-built models to best suit your industrial 3D printing applications and production needs. Our vacuum furnaces provide reliable temperature uniformity and control. Additionally, with a wide range of heating parts, accessories, alumina tubes, and heating elements, we deliver the resources needed to ensure an always successful, efficient, and quality-controlled manufacturing process.

High-Temperature Furnaces for 3D Printing Applications

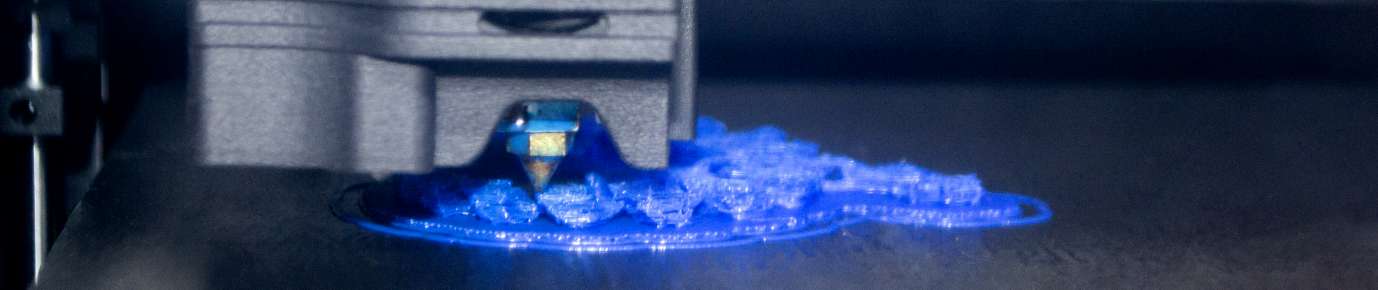

Heat treating 3D parts involves heating your part to a temperature right below its melting point and cooling it down slowly. Heat-treating 3D parts reduces internal stress in molded components and makes those parts stronger and less inclined to warping. In the industrial 3D printing process, plastic is melted and ejected through a nozzle, and quickly after, the plastic material cools off and creates the desired shape. Unfortunately, this rapid cooling causes the plastic material to cool irregularly, which leads to inner stress points between layers of prints. To confront this issue, you can safely heat-treat your 3D parts using one of our high-temperature furnaces for 3D prints. Browse our collection of industrial vacuum furnaces for 3D printing applications.

Sentro Tech STT

This economical sintering tube furnace makes small lab samples from 3D metal printing parts.

Choose the right furnace process tube for your application:

- Alumina (99.5%) tube for tube ID up to 3.5” and max sintering temperature up to 1700oC

- Mullite tube for tube ID up to 7” and max sintering temperature up to 1400oC

Sentro Tech STV

A versatile vacuum and controlled atmosphere furnace for 3D metal part printing. This low-cost sintering furnace uses a 1700oC grade ceramic fiber line and molybdenum silicide heating element. Operate firing cycles and alter atmosphere conditions during the operation cycle from oxidizing such as air to an inert atmosphere or argon/nitrogen to a rough vacuum (10-1 torr).

Designed for accurate air/inert gas flow rate control, these furnaces provide accurate temperature control, excellent temperature uniformity, long-lasting performance, and safe operations. It is ideal for laboratories and production for temperatures up to 1600oC.

- Max Vacuum (Torr) 10-1 Torr Vacuum

- Max pressure: 1100 Torr

- Controller: Eurotherm Nanodac 100 program x 20 segments per program, USB and EtherNet plugs, data recording and computer communication. Temperature and vacuum data are recorded in Eurotherm Nanodac

- Instrutech vacuum pressure gauge, a measurement from 0.001 torr to 1100 Torr

- Welch Vacuum pump

- Type B thermocouples

Sentro Tech STHV

Another Sentro Tech model for 3D metal part printing, consider the STHV as a versatile high-vacuum and controlled atmosphere furnace. This low-cost sintering furnace uses 1700oC grade high alumina ceramic lining and a molybdenum heating element.

- Max Vacuum (Torr) 10-4 Torr Vacuum

- Controller: Eurotherm Nanodac 100 program x 20 segments per program, USB

- and EtherNet plugs, data recording, and computer communication. Temperature and vacuum data are recorded in Eurotherm Nanodac

- Instrutech high vacuum gauge WASP WGM 701, a measurement from 760 torr to 7.6 x 10-10 torr

- Osaka Turbo Molecular Pump System, 450L/S, 10-9 torr Ultimate pressure, DN 160 ISO-F include TC 353 Digital display

- Edwards NXDS10i oil-free scroll pump 7.5 CFM0.005 Torr ultimate base pressure

- Two type S thermocouples: one for control and one for over temperature high alarm

Sentro Tech STHV

Sentro Tech’s high-vacuum furnace features vertical and horizontal door opening for 3D metal printing applications. This high-vacuum sintering furnace uses molybdenum plate shielding, or retort design, and a molybdenum heating element.

- 1400oC Max Vacuum (Torr) 10-5 Torr Vacuum

- Controller: Eurotherm Nanodac 100 program x 20 segments per program, USB

- and EtherNet plugs, data recording, and computer communication. Temperature and vacuum data are recorded in Eurotherm Nanodac

- Instrutech high vacuum gauge WASP WGM 701, a measurement from 760 torr to 7.6 x 10-10 torr

- Osaka Turbo Molecular Pump System, 10-9 torr Ultimate pressure Edwards NXDS10i oil-free scroll pump with 0.005 Torr ultimate base pressure

- Two type S thermocouples: one for control and one for over temperature high alarm

To meet specific requirements or dimensions, contact a Sentro Tech representative today to learn about our custom-built high-temperature furnaces and accessories. Don’t hesitate to reach out to us if you have any questions about industrial 3D printing, and browse our industrial furnaces and ovens today! We have vacuum furnaces, sintering furnaces, tube furnaces, oxygen furnaces, and much more.

Address: 21294 Drake Rd., Strongsville, OH 44149 Phone: (440) 260-0364

Copyright Sentro Tech