Solar Furnaces

Questions? Contact Us!

High-Temperature Solar Furnaces

From large-scale solar power towers to more individualized solar-powered furnace applications, the high-temperature furnace is an efficient and practical source of converting sunlight into electricity. During this process, highly reflective, parabolic mirrors collect the sun’s energy. This collected energy is then used to power the furnace and create steam. This steam by-product is ultimately used to power the turbines and produce electricity.

Because of the exacting control and tolerances required during this process, a solar heat furnace in a power plant must offer a unique combination of versatility and temperature consistency. At Sentro Tech, our vacuum and atmosphere-controlled furnaces are engineered to deliver this consistency. Each vacuum furnace allows for multi-atmosphere processes in one cycle. Plus, the atmosphere condition can be altered during the operation cycle. With accurate air/inert gas flow rate control, reliable temperature uniformity, and temperature accuracy, our solar furnaces are ideal for generating power. Plus, our alumina tubes provide a protective atmosphere during heat applications.

Benefits of Atmosphere-Controlled Solar Furnaces

Some of the benefits of a vacuum-controlled solar furnace heat-treating process are that there are no oxides present, results are clean, and there is little to no distortion. Depending on your project, the primary function of atmospheric-controlled heat treating is to take your parts and improve the material’s mechanical qualities by making it harder and wear-resistant. With solar furnace technology, you can utilize the power generated by solar energy to control a vacuum-controlled furnace that removes all the air out of the oven, which leads to exceptional results.

High-Temperature Solar Heat Furnaces

- 1300°C Vacuum and atmosphere-controlled furnace: Features a maximum working temperature of 1300°C in a vacuum, inert atmosphere, and air.

- 1600°C Vacuum and atmosphere-controlled furnace: Features a max working temperature of 1600°C in air and inert atmosphere and delivers excellent temperature uniformity

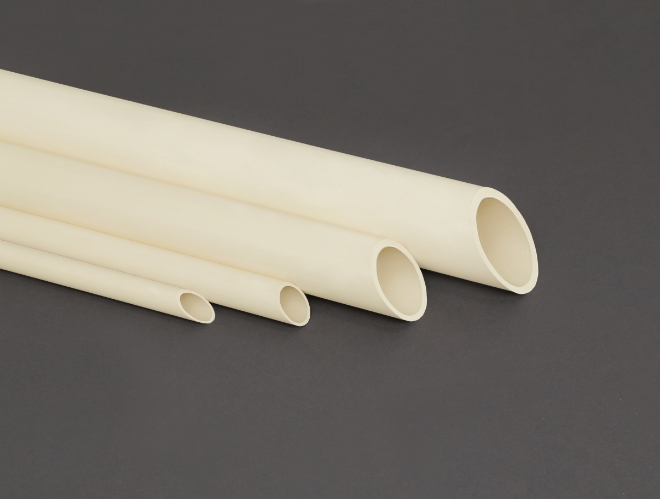

- Alumina ceramic tubes: Features 99.5% to 99.8% high purity and offer elevated temperature stability.

Contact a Sentro Tech representative today to find out how we can serve all your solar furnace needs.

Address: 21294 Drake Rd., Strongsville, OH 44149 Phone: (440) 260-0364

Copyright Sentro Tech