How Does Additive Manufacturing Work?

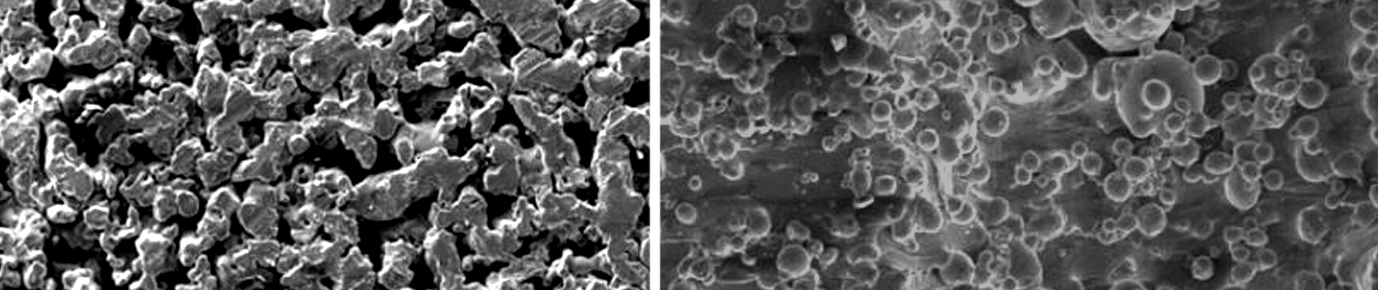

Additive manufacturing deposits material – usually in layers – to form three-dimensional objects. The 3D printing process was introduced in 1980 as a cost-effective way to create plastic parts and prototypes. Thanks to advances in technologies, you’re now able to create 3D objects in metal and ceramics as well as plastic. For 3D metal printing, powder bed fusion is preferred over direct energy deposition. In the powder bed fusion method, a laser or electron beam fuses metal powder particles point-by-point, building up layers until the object grows to its final form.

What Is a Vacuum Sintering Furnace?

Sintering is defined as creating a solid material mass using heat and pressure – without liquefying the material. Vacuum sintering is a heat treatment used to join parts with the least waste to produce consistent components without seams, fillers or joints. The components treated using a vacuum sintering furnace are often intricate, delicate and tricky to make. Benefits of vacuum sintering include:

- Superior Quality

- Bright, Clean Components

- Fewer Imperfections

- Flexibility in Production

- Easy care

Why Does 3D Metal Printing Require a Vacuum Sintering Furnace

Despite the expense, metal 3D printing equipment is not a stand-alone operation. Components created through 3D metal printing still require meticulous thermal sintering to help them achieve the requisite hardness, size and density. If you fail to take this essential finishing step, you may wind up with faulty components or parts that require extensive mechanical finishing.

How Has the 3D Printing Process Been a Game-Changer?

3D printing equipment has revolutionized the future of manufacturing in three main areas:

- Rapid Prototyping: As well as expanding the breadth of materials used to create a prototype, 3D printing has also cut the time required to produce a prototype and enhanced the functionality of the process overall. This has resulted in more efficient prototypes, fewer iterations and lower costs. (Selective heat sintering is a viable method for this type of 3D printing.)

- Design & Testing: Desktop 3D printing equipment has become so commonplace that anyone can have a printer on their desk. Designs can be replicated in 3D without the need to order a prototype from a vendor.

- Short Run Manufacturing: There have been many advances over the years in the kinds of materials available for additive manufacturing. While traditional manufacturing may not be going away anytime soon, for short runs, 3D manufacturing presents a workable solution with components that can be produced quickly.

Practical Industry Applications for 3D Metal Printing

Many industries have come to rely on 3D metal printing. From base metals to precious metals, the variety of materials implemented in 3D printing is impressive. Thanks to global innovation, the use of additive manufacturing in metal printing has become essential, particularly in these industries:

- Automotive: Turbine hubs, synchronizer system parts and gear shift components are just a few of the metal parts produced using additive manufacturing.

- Aviation/Aerospace: Using 3D metal printing, engineers have discovered they can create complex parts for engines and spacecraft that weren’t possible using traditional methods. And they’re able to use the essential metals (such as aluminum and titanium) required for aeronautical flight conditions.

- Medical: Additive manufacturing produces parts in medical equipment, prosthetics and surgical implants.

Sentro Tech Has the Best Vacuum Sintering Furnace for 3D Metal Printing

Our vacuum sintering furnaces give you reliable temperature uniformity and control to ensure a successful finish to your additive manufacturing process. All our high-temperature furnaces are delivered with our 100% satisfaction guarantee. As experts in furnace technology, we’ve served our customers for over 20 years and are proud to be represented in 18 distinct industries, from dentistry to solar energy. Learn what type of vacuum sintering furnace for 3D printing technology will work for you. Or contact us anytime with your questions about our products or services.